-

Call

-

Whatsapp

9825014048

-

Location

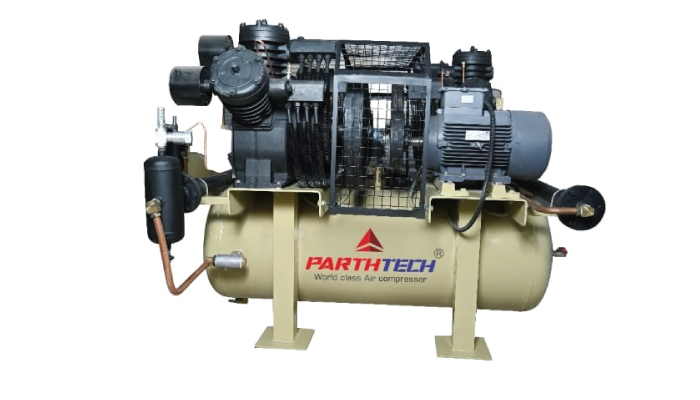

High Pressure Duplex Compressor

High Pressure Duplex Compressor

Application: Powe Sector, Plastic Industries, Specially Designed By Air Compressor For Pet Bottles/ Jars Manufacturing Units.

A High Pressure Duplex Compressor is a specialized type of air compressor designed for applications requiring extremely high air pressures. It consists of two compressor units, often referred to as "duplex," that operate alternately.

These units work in tandem to provide a continuous supply of compressed air at exceptionally high pressures, typically exceeding 1,000 psi (pounds per square inch).

High Pressure Duplex Compressor

Use of High-Pressure Air Compressors

Highly compressed air finds advantages in various areas due to its ability to deliver compressed air at high pressures. Some of the main applications are:

- Industrial Applications: High-pressure gases are needed in the construction, automotive, petrochemical and other industries for applications such as pneumatic equipment powering, leak testing and automation facilitation.

- Scuba Diving and Breathing Gas: These compressors play an essential role in providing breathing gas for scuba divers and firefighters, keeping the air quality safe.

- Automotive Industry: High-pressure air compressors help with tyre blowouts, paint spray and vehicle accumulation.

- Medical and healthcare products: Used in medical devices such as ventilators and dental machines, where high-pressure clean air is required.

- Space and Aircraft: High-pressure gases are inevitable in aircraft landing systems, cabin pressurisation, and aircompressor.

- Bass Storage and Transportation: High-pressure gases, including natural gas and hydrogen, store and transport gases.

Choosing the Proper High-Pressure Air

Several factors are considered when selecting an appropriate compressed air pressure, including the specific application, required level of pressure, and budget constraints. In addition, you need to decide between oil-free and lubricated compressors, each with its own advantages and limitations.

Advantages of High-Pressure Air Compressor

High-pressure gases offer several advantages, including accuracy and efficiency. They ensure the proper functioning of critical equipment and procedures while maintaining safety standards.

Control of High-Pressure Gases

Proper maintenance is essential to ensure the longevity and reliability of your high-pressure air compressor. Regular inspections, lubrication and adherence to safety procedures are crucial for maintenance.

20 HP High-Pressure Air Compressor: Detailed View

For applications requiring a 20 HP high-pressure air compressor, we discuss basic features, best practices, and performance and efficiency considerations in more detail.

High-Pressure Breathing Air

Ventilators used to breathe air are life-saving devices. We examine strict standards and regulations for their use, ensuring clean and safe air.

High-Pressure Air for Automotive Tyres

Portable high-pressure pneumatic tyres have become a necessity for car owners. We will discuss their usefulness, efficiency and maintenance tips for high-pressure flying tyres.

Top Manufacturers and Suppliers

Learn about the basics of the air compressor system industry, including customer reviews and recommendations to help you make a decision.

Cost Consideration

Understand the pricing of air compressor and how to create an adequate budget for your specific needs.

Solving Common Problems

Identify and address common problems with high-pressure air compressor. And know when to seek professional help.

Future Trends in Air Compressor

Explore the latest developments in radiation technology, including sustainability and environmental considerations shaping the industry's future.

Conclusion

High-pressure air compressor are versatile and interchangeable devices important in many applications. Investment in quality and performance ensures efficiency and delivers reliable results across applications.

Features of High Pressure Duplex Compressor

Features:

1. Special Pressure

High-Pressure Air Compressor: These compressors are designed to supply air at pressures well above the standard 125 psi. Depending on the design and application, compressed air can be provided at pressures up to 3,000 psi.

2. Strong Horsepower

20 HP High-Pressure Air Compressor: The 20 HP (Horsepower) rating ensures that the compressor provides enough power to maintain high-pressure

3. Specific Closed Control

High-Pressure Breathing Air Compressor: Precision pressure control mechanisms ensure clean and safe purification air supply, complying with stringent industry standards.

4. Portable and Compact Design

High-pressure air pumps for automotive tyres: The portable units are compact and easy to transport, making them ideal for inflating high-pressure tyres where necessary.

5. Durability and Reliability

All Features: Airbags are designed with durability in mind, ensuring that they can withstand the rigours of industrial treatment or automotive conditions

6. Oil-Free Options

High-pressure air compressor: Some devices are designed in oil-free systems. They ensure that the air remains free of contaminants to minimize maintenance requirements.

7. Efficient Cooling System (H2) 20 HP high-pressure air compressor: Advanced cooling system prevents overheating during extended operation, maintaining productivity and efficiency.

8. Safety Measures

High-pressure breathing gas: Safety features such as internal monitors ensure clean breathing air.

9. Low Noise Performance

All types: Many high-pressure air compressors are designed to operate quietly, reducing noise pollution.

10. Easy-to-Use Controls

High-Pressure Air Pump for Car Tyres: Intuitive controls and gauges make it easy to operate, making it easy to operate and adjust the pressure

11. Specific Equipment

All types: A variety of accessories and accessories are available to tailor the compressor to a specific application, ensuring versatility and efficiency

12. Adherence to Corporate Standards

High-Pressure Breathing Air Compressor: Compressors used in breathing air comply with stringent industry standards and certifications to ensure safety.

13. Energy Efficiency

All types: Energy-efficient models are designed to reduce electricity consumption, helping to save costs and be environmentally sustainable.

14. Maintenance Warning

High-pressure air compressor: A refined air compressor can have maintenance alerts to ensure timely operation and reduce downtime.

15. Longevity and Performance

All types: High-end features and construction contribute to high-pressure air filters' longevity and consistent operation.

| Model | Max. Pressure | FAD CFM |

Motor H.P. |

Air Receiver (Ltr) | |

| Kg/CM 2 G | PSIG | ||||

| PT 30 MS | 35 | 500 | 4.5 | 3 | 150 |

| PT 125 MS | 35 | 500 | 21 | 12.5 | 300 |

| PT 200 MS | 70 | 1000 | 37 | 20 | 500 |

| PT 200 MS(DUPLEX) | 70 | 1000 | 74 | 20x2 | 500/750 |

| PT 200 MS - M | 25 | 355 | 54 | 20 | 500 |

| PT 200 MS-M(DUPLEX) | 25 | 355 | 108 | 20x2 | 500/750 |

| PT 300 MS - M | 25 | 355 | 68 | 25 | 500 |

| PT 300 MS-M(DUPLEX) | 25 | 355 | 136 | 25X2 | 750 |

Spray Painting

Single-stage air compressors are essential tools in the field of spray painting, where precision, consistency, and quality are paramount. These compressors provide a continuous source of compressed air, which is indispensable for the operation of paint spray guns and other painting equipment.

FAQs

Frequently Ask Questions

High-pressure compressors are designed to deliver compressed air at much higher pressures compared to standard compressors. Although standard compressors are universally suitable for applications, higher pressure compressors are designed for applications that require air accuracy and filling

High-pressure compressed air can produce compressed air with pressure levels typically ranging from 2,000 to 6,000 pounds per square inch (psi) or more, depending on the specific application

High-pressure compressed air is used in a variety of industries, including construction, aerospace, petrochemical, healthcare, firefighting, scuba diving and automotive

Yes, high-pressure air compressors specially designed for breathing air are safe and necessary to provide clean, pollution-free air for divers, medical facilities, and the firefighters using breathing apparatus

Yes, high-pressure air pumps designed for automotive tires are more effective at inflating tires quickly and maintaining the recommended pressure levels. It is commonly used in automobile manufacturing plants.