-

Call

-

Whatsapp

9825014048

-

Location

Air Audit

PARTHTECH Air Compressor Research Report

There are short, medium and long-term energy conservation measures, financial estimates, and analyses included in the audit report. These recommendations use databases and fact sheets from measurements and tests in your factory and the field. In addition, we assist in the implementation and performance management of our energy conservation proposals with access to the expert services of our engineers and user training.

With energy costs rising, the efficiency and performance of your compressed air systems have never been more critical. Potential energy savings reduce your business's impact on patronage and your bottom line. We help you reduce power consumption, compressed air system weight, consumption, and wear and tear, extending the overall life of the compressed air system.

Compressed Air System Efficiency Calculations Provide Detailed Scores For:

- Total systems scientific method.

- Demand-side flow analysis [end of application].

- Supply-side flow optimization.

- Total measurement of power consumption and power factor.

- Actual flow, pressure & power requirements.

- Compressed air & dew point [where applicable].

Airflow System:

- Air leak detection, quantification, and pricing.

- Wind turbine improvement recommendations.

- Air leakage monitoring [data for repetitive analysis].

- Targeting of escort upgrades.

Detailed Design and Technical Analysis:

- Flow demand classification and optimization

- compressed air system distribution

- probability validation

- cost savings analysis

- recommendations and conclusions

- plan to keep reducing energy costs

UNDERSTANDING COMPRESSED AIR AUDITS

Energy is a precious commodity, and compressed air is an expensive commodity that finds applications in a wide range of industries; hence, the judicious, careful and energy-efficient use of compressed air efficiency is essential because it affects every operational function. With more than 60 years of research and innovation in ventilation, equipment and services, ParthTech offers compressed air solutions for every need. Our proven expertise in these areas has led to a better understanding of compressed air handling activities and pioneering methods and tools to estimate energy consumption.

Our team of appliances, electricity energy, and experienced mechanical engineers perform numerical analysis and train the end users in the power plant to ensure that the most efficient use of energy is approximate.

Energy consumption auditing is an essential process. Energy conservation projects' estimation, design, commissioning and performance management require comprehensive knowledge and expertise in many areas.

The Purpose and Usefulness of Energy Audits in Compressed Air Systems Are:

- Precision measurement of the compressed air system.

- The amount of energy required to produce and consume a product decreases.

- Catching any unused energy.

- Energy recycling and efficiency.

We enable energy-intensive businesses to deploy and manage energy efficiently, helping to significantly reduce electricity costs, make their operations more competitive, and increase overall efficiency and profitability.

The Programs Aim to Achieve a Combination of the Following Benefits:-

- Accurately controlled compressed air handling systems.

- Energy consumption of compressed air is reduced.

- Elimination of all waste.

- We reduced operating & maintenance costs.

- We are reducing equipment downtime.

- Increased coordination.

- Improvements in production and volume.

- Significant cost savings and revenue growth.

- The strategic value of performance in measuring global industry standards.

FAQ

Frequently Ask Questions

An Air Audit is a comprehensive assessment of your compressed air system to identify inefficiencies, leaks, and potential energy savings.

An Air Audit helps optimize your compressed air system, reduce energy costs, minimize downtime, and improve overall efficiency.

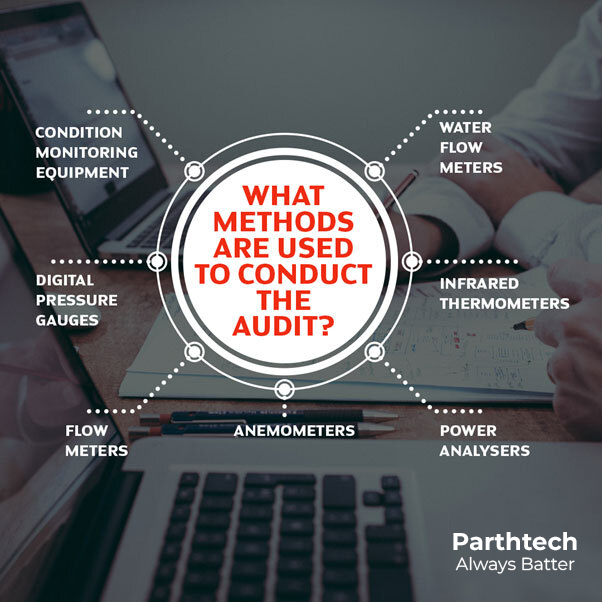

An Air Audit involves onsite inspections, measurements, data analysis, and recommendations for optimizing system performance.

Benefits include energy savings, reduced maintenance costs, increased productivity, and environmental sustainability.

It is recommended to conduct Air Audits regularly, typically every 1-2 years, to ensure optimal performance and identify any changes in system requirements.